Stainless Steel Polishing Services — Kosmo Engineering

Polished stainless steel performs better — in hygiene, corrosion resistance, cleanability, and appearance. At Kosmo Engineering we deliver industrial-grade polishing and electropolishing services designed for food, pharmaceutical, beverage, chemical, and architectural applications. Whether you need a sanitary mirror finish for a tank, a uniform satin finish for a visible façade, or precise weld blending for hygienic piping, our team provides durable, certified results.

Why Polishing Matters

A proper finish is more than visual: it reduces surface roughness where bacteria and contaminants hide, improves corrosion resistance by promoting passivation, and lowers cleaning time and chemical usage. In regulated environments (food or pharma), the right finish helps you meet hygiene and audit requirements.

Our Polishing Services

We provide both mechanical and electrochemical finishing, plus ancillary services to deliver a turnkey result:

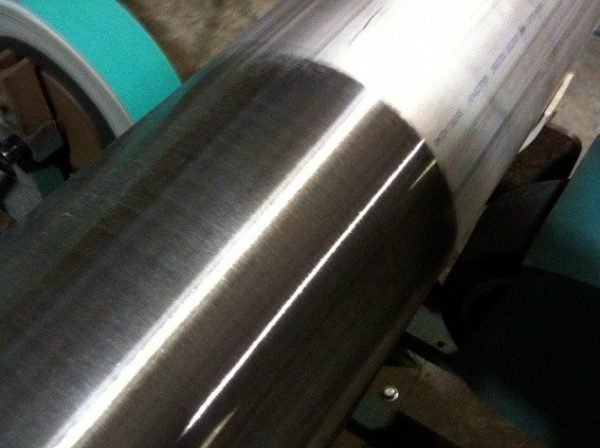

Mechanical Polishing (Abrasive & Buffing)

Coarse-to-fine grit sequences to remove weld spatter, scratches, and scale. Produces No. 1 → No. 8 finishes depending on spec.

Electropolishing (Electrochemical)

Levels microscopic peaks, reduces Rz/Ra values, and enhances passivation for superior corrosion resistance and cleanability. Ideal for sanitary equipment.

Satin / Brushed Finishes (No. 4)

Consistent directional grain for aesthetic & anti-glare surfaces.

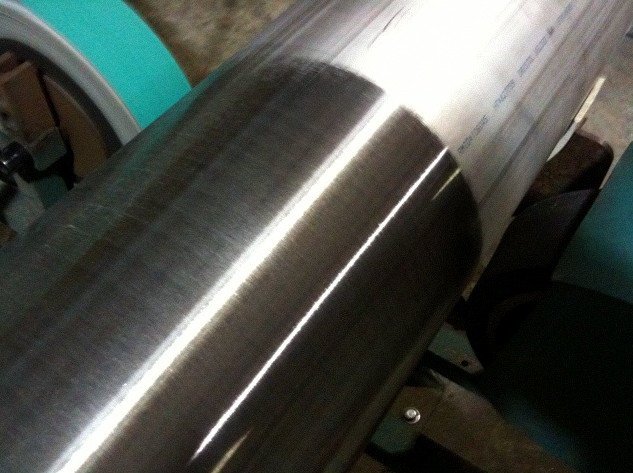

Mirror & High-Gloss Finishes (No. 7 / No. 8)

High-reflectivity polishing for architectural and decorative applications.

Weld Blending & Seam Smoothing

Seamless transition between weld and parent metal for hygienic surfaces.

Chemical Passivation & Pickling

Remove embedded iron and re-establish the chromium oxide passive layer.

Surface Rehabilitation / Repair

Restore corroded or scratched surfaces to serviceable condition.

On-site Polishing for Large Equipment

Site teams for tanks, piping networks, ducts, and architectural panels.

Inspection & Certification

Finish verification, Ra/Rz measurement on request, photographic before/after records.

Our Process (step-by-step)

Inspection & Quotation

Visual and dimensional assessment. Recommend finish grade, deliverable roughness (Ra), and method (mechanical vs electropolish).

Preparation

Degreasing, decontamination, masking sensitive fittings. Select abrasives and tool path.

Mechanical Pre-Polish

Remove heavy marks with coarse abrasives; progressively refine to target grit.

Electropolishing (optional / as specified)

Controlled electrochemical smoothing for sanitary surfaces and to enhance passivation.

Weld Blending & Finishing

Blend welds; match surrounding texture (brushed, satin, or mirror).

Passivation & Rinse

Chemical passivation to remove free iron and strengthen corrosion resistance. Final rinse and dry.

Quality Check

Surface roughness (Ra/Rz) test on request, visual inspection, and photographic records.

Handover & Recommendations

Care instructions, maintenance schedule, and documentation for compliance/audits.

Finishes We Deliver

- No. 4 Satin / Brushed — hygienic, non-reflective, hides minor scratches. Great for food contact surfaces.

- No. 6 / No. 7 Polished — semi-bright; good for intermediate decorative/functional needs.

- No. 8 Mirror — ultra-smooth, high reflectivity for architectural and display applications.

- Electropolished Finish — lowest Ra, easiest to sanitize, best for pharma, dairy, and biotech.

Advantages & Benefits

Hygiene & Regulatory Compliance

Lower surface roughness reduces microbial adherence so cleaning is more effective — critical for food & pharma.

Improved Corrosion Resistance

Easier & Faster Cleaning

Better Product Quality

Aesthetic & Brand Value

Reduced Downtime

Cost-Effective Restoration

Traceability & Certification

We provide inspection records, Ra/Rz readings, and photos — useful for audits and certifications.

Typical Specifications we work to

- Food-grade / Sanitary finishes: Ra ≤ 0.8 µm (electropolished often Ra ≤ 0.4 µm)

- Architectural high-gloss: No. 7 / No. 8 mirror polish, visual quality per sample

- Brushed / Satin: Directional finish, 120–240 grit equivalent

(We’ll confirm target Ra and finish in the quotation stage.)

Turnaround & Capacity

- Small parts: 1–5 days typical (depends on batch & finish)

- Medium assemblies / moderate weld blending: 5–12 days

- Large tanks, on-site jobs: scheduled and executed to minimize production disruption — lead time quoted per project

(Exact turnaround depends on scope, surface condition, quantity, and whether electropolishing is required.)

On-Site Polishing & Safety

We provide mobile polishing teams for installations and large equipment where transport is not feasible. All on-site work follows strict safety protocols, protective masking of sensitive areas, and coordination to maintain plant hygiene standards.

Maintenance Tips

- Use non-abrasive cleaners and soft cloths for routine cleaning.

- Avoid chloride-based cleaners on lightly finished surfaces; use recommended sanitary detergents.

- Rinse and dry after cleaning to prevent water spotting.

- Inspect seams and welds regularly; re-polish or passivate if discolouration appears.

Frequently Asked Questions

What’s the difference between mechanical polishing and electropolishing?

Mechanical polishing uses abrasives to smooth the surface; electropolishing is an electrochemical process that levels microscopic peaks and improves passivation — electropolish yields lower Ra and better hygienic properties.

Can you match an existing finish?

Yes — we match satin direction, mirror reflectivity, and measured Ra values. We sample and approve before full production.

Do you provide Ra/Rz measurement?

Yes — we can provide surface roughness measurement and certificates on request.

Is on-site polishing possible?

Yes — we perform on-site polishing for large tanks, piping networks, and fixed installations.

How do I prepare parts for polishing?

Remove loose fittings, empty tanks, and isolate electrical components. We can provide a preparation checklist.

Ready to Start Your Project?

Fill out the form below and our metal (Stainless Steel) polishing experts will contact you shortly to discuss your requirements.

Let’s create durable, high-precision results — together.