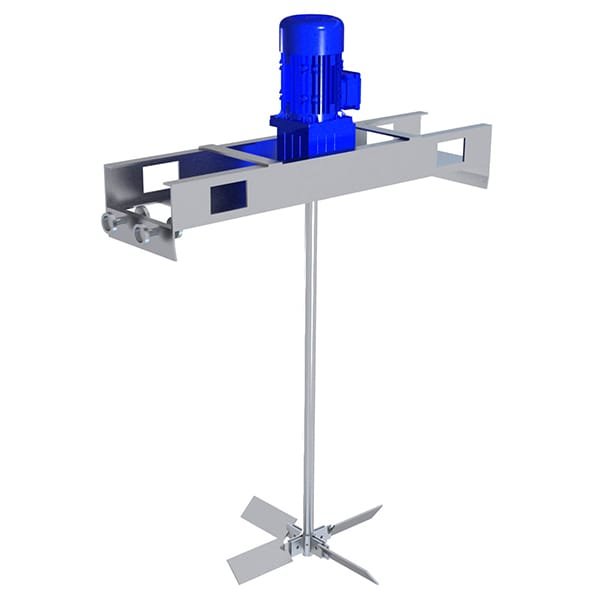

1. Top Entry Agitators

Designed for large tanks and heavy-duty mixing.

Best for: High-viscosity liquids, emulsions, and slurry mixing.

2. Side Entry Agitators

Ideal for large storage tanks and continuous mixing.

Best for: Blending, preventing sedimentation, maintaining uniformity.

3. Bottom Entry Agitators

Provides fast, efficient shear and easy tank cleaning.

Best for: Hygienic applications in food & pharma.

4. High Shear Agitators

Offers rapid dispersion and emulsification.

Best for: Creams, gels, chemicals, and homogenization processes.

Our agitators are suitable for a wide range of materials, including:

Description

Industrial Agitators for Precision Mixing

Kosmo Engineering manufactures high-efficiency industrial agitators designed to deliver consistent, uniform, and controlled mixing across multiple applications. Built for durability and performance, our agitators handle a wide range of viscosities and mixing environments — making them ideal for food processing, chemical production, pharmaceuticals, beverages, cosmetics, and other industrial sectors.

Whether you need gentle blending, high-shear mixing, emulsification, or suspension, our agitators ensure reliable and repeatable results for every process.

Key Features

-

Robust MS or Stainless Steel Construction for long-term industrial use

-

Customizable impeller designs to match viscosity, mixing speed, and process needs

-

Energy-efficient motors with stable torque and smooth operation

-

Consistent mixing performance for powders, liquids, pastes, and semi-solids

-

High chemical resistance suitable for aggressive formulations

-

Low maintenance design with easy cleaning and servicing

-

Option for sanitary/hygienic designs for food and pharma applications

Applications

Our industrial agitators are widely used in:

-

Food & Beverage: Sauces, syrups, dairy blends, oils

-

Chemical Industry: Solvents, resins, detergents, emulsions

-

Pharmaceuticals: Liquid medicines, suspensions, ingredients

-

Cosmetics: Creams, lotions, gels

-

Water Treatment: Flocculation, mixing tanks, chemical dosing

Why Choose Kosmo Engineering Agitators?

-

Precision Mixing: Ensures uniform product texture, stability, and consistency

-

Process Efficiency: Reduces mixing time and energy consumption

-

Custom Design: Tailored impellers, shafts, motor power, and tank compatibility

-

Industrial Durability: Reliable performance under continuous operation

-

Scalable Solutions: Available for small-batch to large industrial tank installations

-

Expert Engineering Support: From selection to installation and maintenance

Reviews

There are no reviews yet.