Brusher Roller Conveyor – Conveying & Surface Cleaning in One System

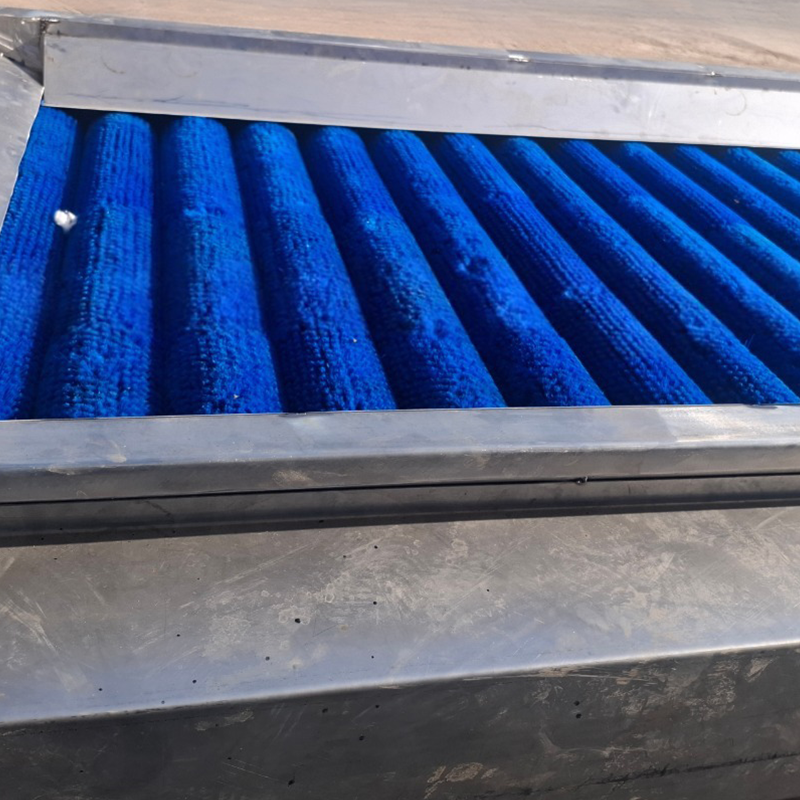

Kosmo Engineering’s Brusher Roller Conveyor is a specialized material handling system designed to transport products while simultaneously cleaning, brushing, or polishing their surfaces. This dual-function conveyor integrates brush-equipped rollers within a robust roller conveyor structure, making it ideal for automated production lines where surface cleanliness and preparation are critical.

By combining gravity roller conveyor principles with powered brush rollers, this system ensures efficient product movement along with continuous surface treatment—eliminating the need for separate cleaning or finishing stations.

Working Principle of Brusher Roller Conveyor

A brusher roller conveyor operates by moving products over rotating or stationary brush rollers. As items travel along the conveyor, the integrated brushes gently remove dust, debris, chips, residues, or surface contaminants. Depending on the application, the brushes can be powered or passive, allowing flexibility for light cleaning or more intensive surface preparation.

This system can be configured as a gravity roller conveyor or a powered roller conveyor, depending on production requirements.

Reviews

There are no reviews yet.