Liquid Homogenizer Machine – Kosmo Engineering

The Liquid Homogenizer by Kosmo Engineering is a high-pressure industrial mixing system designed to achieve uniform emulsification and blending of liquid products. Built with precision and power, it ensures fine dispersion of particles for a smooth, stable, and homogenous output in food, dairy, chemical, and pharmaceutical production lines.

Machine Overview

Kosmo Engineering’s Liquid Homogenizer operates through a three-piston plunger pump mechanism driven by a heavy-duty motorized gear drive, which applies intense pressure to liquid mixtures.

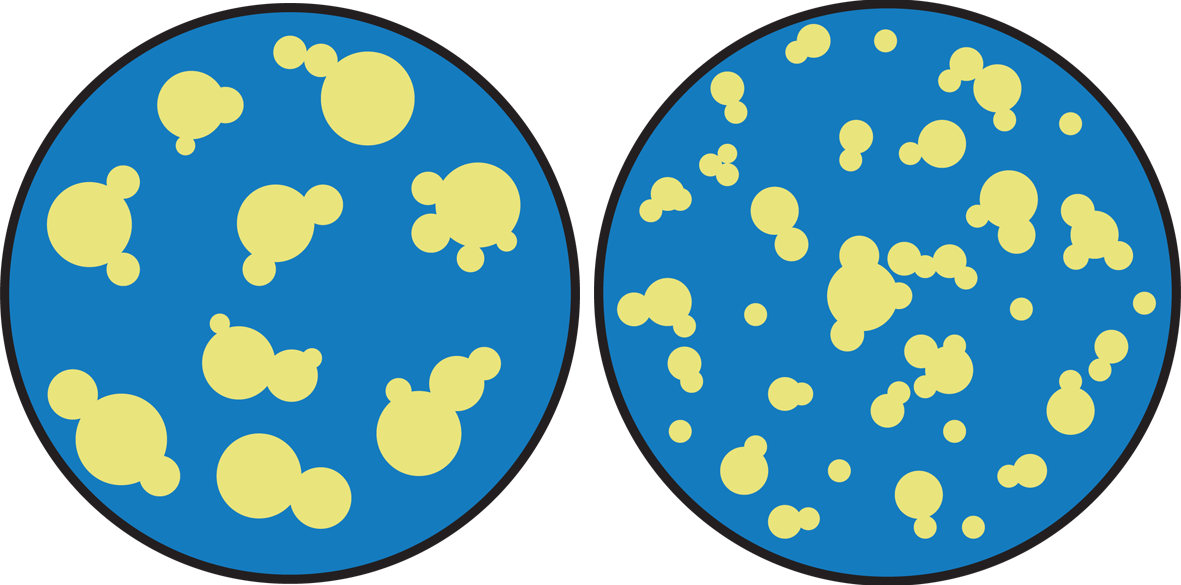

This high-pressure action forces the liquid through a narrow gap, breaking down particles and forming strong molecular bonds between immiscible substances like oil and water.

The result is a perfectly homogenized liquid mixture that maintains texture, taste, and stability — ideal for high-quality product manufacturing.