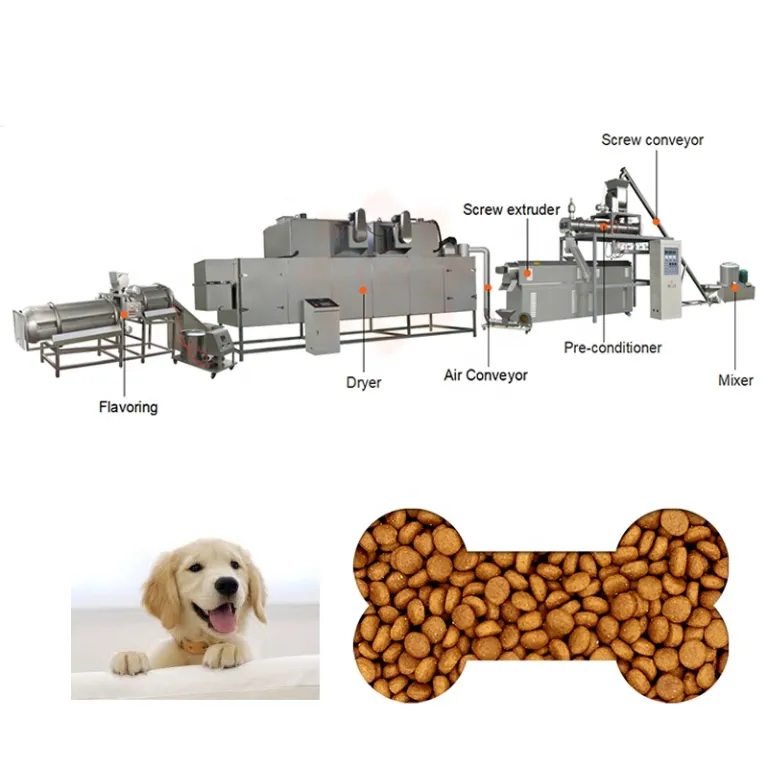

Complete Pet Food Processing Line by Kosmo Engineering

Each pet food production plant by Kosmo Engineering includes the following machinery:

-

Ribbon Blender Mixer

-

Screw Elevator Conveyor

-

Extruder (Pellet Forming Machine)

-

Furnace (Bhatti)

-

Dehydration Tunnel Oven (Drying Section)

-

Flavoring Drum

-

Automatic Control Panel System

-

Product Conveyor Systems

The system is designed for 150–200 kg/hour capacity and powered by a 40 HP three-phase electric load.

1. Dehydration Tunnel Oven (SS Conveyor Belts)

Specifications & Features:

| Parameter |

Specification |

| Height |

7 – 7.5 ft |

| Width |

4 ft |

| Length |

12 ft |

| Capacity |

150 – 200 kg/hour |

| Conveyor Belts |

Stainless Steel SS-L304 Mesh |

| Body Material |

Mild Steel (Inner & Outer 2mm) |

| Temperature |

Up to 200°C (Controllable) |

| Insulation |

4″ Rockwool Filled |

| Layers |

5 Conveyor Layers |

Description:

The Dehydration Tunnel Oven ensures uniform drying of pet food pellets. Constructed with insulated double-jacketed walls, the system retains heat efficiently up to 300°C. The SS mesh conveyors allow even airflow, while the VFD control system adjusts belt speed for desired drying levels. Fitted blowers ensure proper heat circulation for consistent moisture removal and texture.

2. Furnace (Bhatti)

Specifications & Features:

| Parameter |

Specification |

| Temperature |

150 – 200°C |

| Gas Burner |

Uni-Gas or Imported (800Kw) |

| Body Material |

Mild Steel (4mm) |

| Inner Lining |

Double jacketed Fireclay & Fire Cement |

Description:

The Furnace provides stable heat supply to the oven via direct gas burners. Equipped with automatic fire cut-off and control panel integration, it ensures optimal temperature maintenance and energy efficiency.

3. Extruder (Pellet Making Machine)

Specifications & Features:

| Parameter |

Specification |

| Height |

5 ft |

| Length |

6.5 ft |

| Capacity |

150 – 200 kg/hour |

| Material |

Mild Steel Frame (2mm) |

| Screw (Worm) |

K-100 Hardened & Chrome-Plated |

| Motor Drive |

12 HP Gear Motor |

| Barrel Temperature |

30 – 50°C |

| Die Options |

3 Interchangeable Sizes |

Description:

The Extruder forms the base shape of pet food pellets using K-100 steel worm screws and chrome finishing for durability. A VFD system controls rotation speed to adjust pellet density and size.

Includes a rotary feeding agitator and die-cutting blades for even extrusion of cat and dog food biscuits.

4. Extruder to Oven Conveyor

Specifications & Features:

| Parameter |

Specification |

| Height |

12 ft |

| Width |

18” |

| Length |

12 ft |

| Belt |

3mm Food-Grade Silicon |

| Material |

Mild Steel |

| Motor Drive |

2 HP |

Description:

Transfers formed pellets from extruder to oven without contamination. Built with a food-grade silicon belt, it ensures gentle handling and uniform feed distribution.

5. Ribbon Blender Mixer

Specifications & Features:

| Parameter |

Specification |

| Height |

4 ft |

| Length |

5 ft |

| Width |

36” |

| Capacity |

550–600 kg/batch |

| Material |

SS-L304 Shell |

| Drive |

12.5 HP (25 RPM) |

Description:

A heavy-duty ribbon blender designed for uniform mixing of raw materials like grains, meat meal, vitamins, and flavor enhancers. Ensures homogeneous blending for balanced nutrition.

6. Screw Elevator Conveyor

Specifications & Features:

| Parameter |

Specification |

| Height |

4.5 ft |

| Diameter |

8” |

| Length |

6 ft |

| Material |

SS-L304 |

| Motor |

3 HP |

Description:

Transfers mixed feed from the blender to the extruder. The stainless steel auger design ensures smooth upward movement with zero product waste.

7. Flavoring Drum

Specifications & Features:

| Parameter |

Specification |

| Height |

4.5 ft |

| Drum Diameter |

24” |

| Length |

8 ft |

| Material |

SS-L304 |

| Drive |

2 HP |

Description:

Applies flavoring oils or coatings to dried pellets. The drum’s inner scrapers and rotating design ensure even seasoning across every piece. Integrated with main control panel.

8. Control Panel

Specifications & Features:

| Parameter |

Specification |

| Height |

4.5 ft |

| Width |

3 ft |

| Depth |

12” |

| Material |

MS (1.5mm Thick) |

| Power Load |

40 HP (3 Phase) |

Description:

Centralized control system with VFDs, relays, emergency cut-offs, and temperature sensors. It controls oven heat, extruder speed, blower circulation, and full plant synchronization.